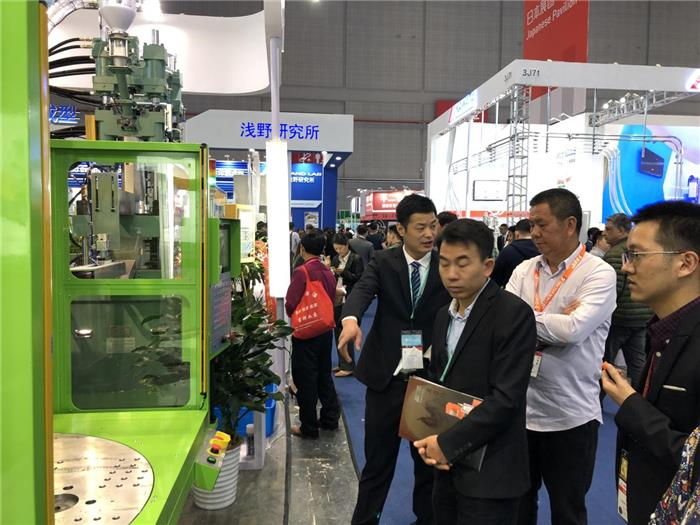

32rd CHINAPLAS – THE WORLD’S LEADING PLASTICS AND RUBBER TRADE FAIR

Exhibition date: 2018.4.24-2018.4.27

Booth No.: 3E63

Address: Hongqiao National Exhibition Center, Shanghai, China

Two-color electric liquid silicon rubber injection molding machine FT-800E-R2-LSR

- The two injection units in the main part of the equipment are all electrically controlled.

- The total pressure part adopts full servo control, which has the characteristics of stable instant start, small rotational inertia, fast response, energy saving and environmental protection, etc. The whole machine is efficient, precise and stable.

- An electric injection molding system is added to the back of the injection molding machine as an injection mechanism, which qualitatively improves the accuracy and the injection position accuracy is less than 0.01mm.

- Suitable for the manufacture of silicone two-color products, products without flash, no color difference, no flow lines, mainly used in the mobile phone shell, watch and other precision products of plastic coating molding.

Hybrid synergy drive rotary injection molding machine FT-800E-R2

- Precision: suitable for insert part within 100 g and complicated mould. Injection precision is controlled with two thousandths.

- High efficiency: mold opening and material storage at the same time, short the molding time.

- Energy saving: hydraulic part is also servo driven, totally five axis armature.

- Silence: Special injection screw and high rigid mechanical structure make the machine run smoothly and quietly.

- Reliable: The perfect combination of electric injection and direct pressure clamping can realize high precision injection and long service life of the mould.

Center turret multiple color and material injection molding machine FT-1200-2CM

- Modular design, multiple efficient and stable injection devices can be selected.

- Each pair of mould in the injection molding station has a special clamping cylinder to provide clamping force. Adhering to the characteristics of the direct press, extend the service life of the mould.

- Small size epicyclic reduction gear unit and special plunger locating device are used on center turret rotating system. It turns quickly and accurately. Optional hydraulic drive or servo motor drive.

- The lifting motion of the center turret is controlled by linear displacement sensor. The speed and position of lifting can be directly adjusted in the operation panel, which is convenient and fast.

- Integration of multiple groups using robots, greatly improve production efficiency.

- It can be upgraded from basic 4 stations to 6 stations and 8 stations, with higher production efficiency.

Two-plate heavy duty injection molding machine FT-1200-R2

- Four-cylinder two-plate vertical clamping construction.

- Lower workbench, easier for operation.

- Total pressure servo control system, precision, power saving, silent.

- Modular design, meet CE safety standard.