Injection machines are a production machine widely used in industry, also known as injection molding machines or injection machines. In China, the production technology of injection molding machines is very mature. The injection molding machine is composed of multiple parts. What are the important components? Feng Tiejun takes you through the four major components of the injection molding machine: the injection system, the clamping system, the hydraulic system and the electrical control system. The four components of the injection molding machine have their own characteristics and functions, together to see the analysis.

(1) Injection system

In injection molding machines, the injection system is arguably the most important component. The injection system includes a plasticizing component, an injection molding base, a hydraulic motor, a seat shifting cylinder, and an injection cylinder, wherein the plasticizing component further includes a screw, a screw head, a nozzle, and the like.

(2) clamping system

The main function of the clamping system is to ensure the closing and opening of the injection mold and the ejection of the product. The clamping system includes a clamping device, a molding device, and an ejection device.

(3) Hydraulic system

The main function of the hydraulic system is to provide the required power for the injection molding machine to meet the various actions that the injection molding machine needs to achieve throughout the process. What is important is that the hydraulic system also meets the pressure, speed, temperature and other requirements required for each part of the injection molding machine. The hydraulic system includes control of the oil circuit such as pumps, hydraulic motors, valves, accumulators, coolers, and piping.

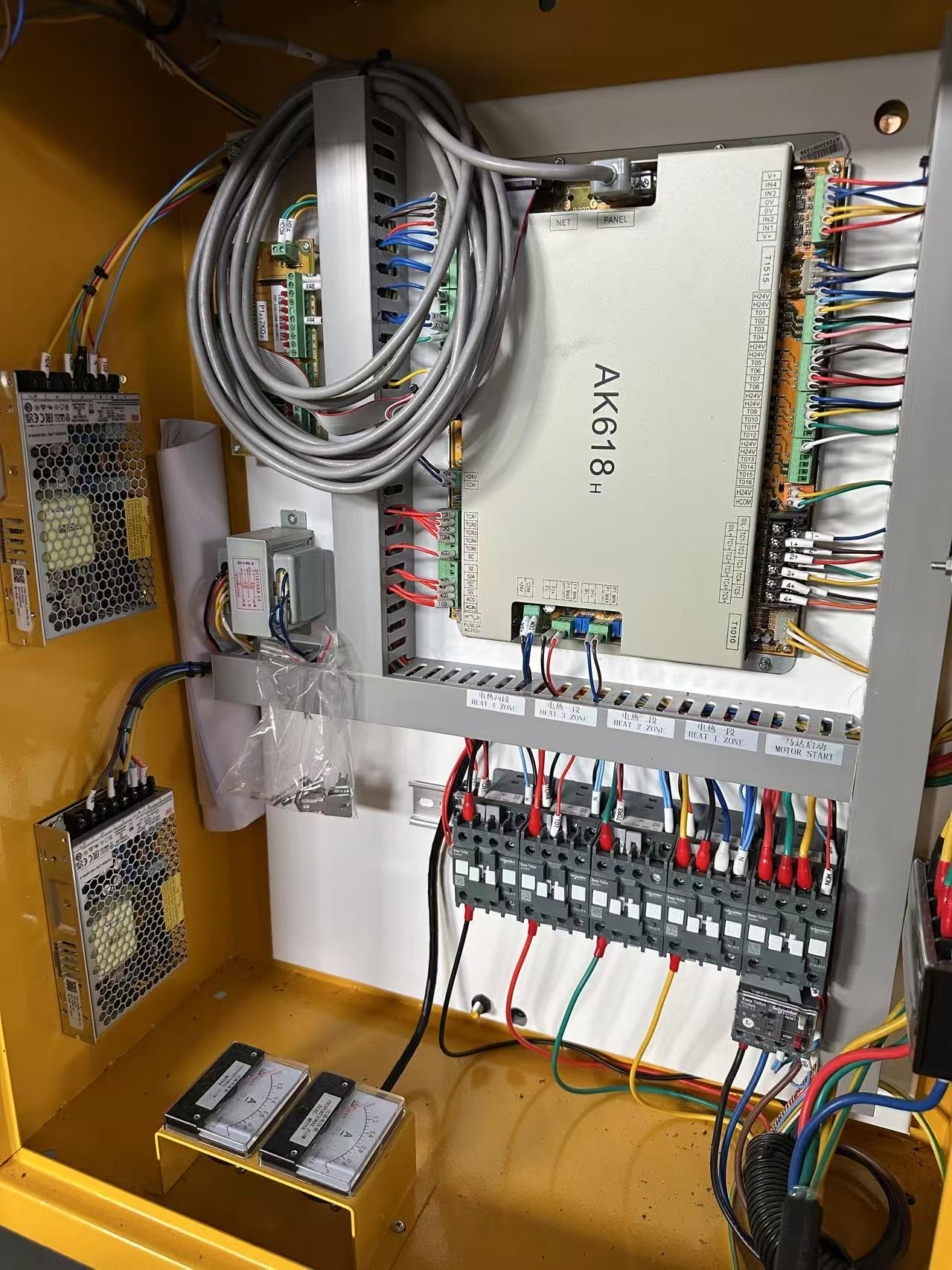

(4) Electrical control system

The electrical control system and the hydraulic system are properly coordinated to achieve the process requirements (pressure, temperature, speed, time) of the injection machine and various program actions. Mainly composed of electrical appliances, electronic components, meters, heaters, sensors and so on. There are generally four control modes, manual, semi-automatic, fully automatic, and adjustment.

Of course, in addition to the above four components, the injection molding machine has other components, such as the control system, and the control system includes motion program control, barrel temperature control, hydraulic pump motor control, fault detection alarm control, and safety protection.